Copper is considered as one of the first metals to be used by humans and has a fascinating origin story dating back to the Bronze Age. In fact, the discovery that with a little bit of tin, copper could be hardened to form bronze alloy is what led to that era in history being christened the Bronze Age. This copper-tin alloy was widely used in the ancient world to make coins, cutlery and tools and the era provided its civilization with the technological advantages that were necessary to advance forward in time.

11,000 years ago when copper was first being put into use, ancient societies had no information about the metal and as a result the metal was under-used. Since ancient societies lacked modern knowledge and scientific know-how about metallurgy they began to use the metal more for decorative ornamental purposes than for its inherent scientific properties.

Ancient men realised that copper on its own was too soft to be used on its own for any purpose which then led them to combine the metal with other metals to strengthen it. The most common combination was with tin to form bronze.

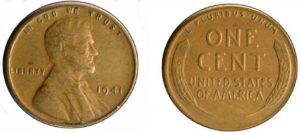

In the US, Copper was one of the metals that was used to make coins along with gold and silver but since it is the most abundant metal, it came to be the least valued. However, today all coins in the US are copper alloys, tossing up the value of copper greatly. In Northern Iraq, copper beads which were more than 10,000 years old were excavated and presumed to have been produced from native copper nuggets.

In the modern world, copper has come to occupy a more central role as an excellent conductor of heat and electricity, making it the perfect metal to be used in electrical equipment like motors and wiring. Copper directly aids and assists in contributing towards advancement of technology in the modern world.

The earliest extraction and smelting of copper ores is believed to be the outcome of experiments while trying to understand what rocks could be smelted. Fast-forward from the era of accidents and experiments to today where copper smelters have sound technical knowledge and advanced technology to smelt copper with minimum production of waste.

Where Sterlite Stands

Sterlite Copper is today, one of India’s most advanced smelters in terms of technology and waste management practices. The smelter has the capacity to produce 4 lakh tonnes of copper per annum and contributes to 34% of India’s copper production.

The smelter functions on the technology provided by Mount ISA Mines, Australia and stands as a stark contrast to early societies which functioned on experimentation. The company is far more environmentally conscious than many other smelters across the world and employs proven energy efficient and environmentally friendly technology such as effluent treatment plants and solid waste treatment plants in addition to being a zero liquid discharge plant.

Copper over the decades made its way into main stream or new markets due to its high electrical and heat conductivity property. In other words, the new age metal is a material of choice for various domestic and industrial purpose today. Comfort electronic goods such as air conditioners, refrigerators, television sets, induction stoves, etc., would not exist without this magic metal which supersedes any other metal on earth for its conductivity.

The evolution is still on the run, due to the realisation of the metal’s application in electrical cars, health sector due to its anti – microbial properties, harnessing renewable energy to create a sustainable earth, etc. We at Sterlite Copper believe that domestically processed copper would equip India to locally manufacture various copper products which would otherwise be too exorbitant to produce.

Официальное получение диплома техникума с упрощенным обучением в Москве

local-urban-eats.mn.co/posts/69456123

Всё, что нужно знать о покупке аттестата о среднем образовании

magik-music.ru/8054-diplom-v-troicke

Узнайте стоимость диплома высшего и среднего образования и процесс получения

disqus.com/by/iygorefremmv/about

Вопросы и ответы: можно ли быстро купить диплом старого образца?

Можно ли быстро купить диплом старого образца и в чем подвох?

Всё, что нужно знать о покупке аттестата о среднем образовании без рисков

Как получить диплом стоматолога быстро и официально

Официальная покупка школьного аттестата с упрощенным обучением в Москве

Всё о покупке аттестата о среднем образовании: полезные советы

Как получить диплом о среднем образовании в Москве и других городах

Как получить диплом стоматолога быстро и официально

Где и как купить диплом о высшем образовании без лишних рисков

Как купить диплом о высшем образовании с минимальными рисками

Диплом вуза купить официально с упрощенным обучением в Москве

Быстрое обучение и получение диплома магистра – возможно ли это?

Диплом техникума купить официально с упрощенным обучением в Москве

Онлайн платформы для творческого подхода к подбору имени, для раскрытия вашего творческого потенциала в выборе имени.

Выбрать имя ребенку http://www.child-name.ru/ .

Парадокс, но купить диплом кандидата наук оказалось не так и сложно

Пошаговая инструкция по официальной покупке диплома о высшем образовании

Профессиональный автосервис в столице, где качество на первом месте.

Автосервисы в москве на карте [url=https://crabcar.ru/]https://crabcar.ru/[/url] .

Как купить аттестат 11 класса с официальным упрощенным обучением в Москве

Официальная покупка диплома вуза с упрощенной программой обучения

Купить диплом о среднем полном образовании, в чем подвох и как избежать обмана?

Официальная покупка диплома вуза с сокращенной программой обучения в Москве

Быстрое обучение и получение диплома магистра – возможно ли это?

Пошаговая инструкция по официальной покупке диплома о высшем образовании

Советы по выбору стоматологии в Минске: цены и качество, здесь.

Зубной стоматология цены [url=http://www.total-implant.ru/]http://www.total-implant.ru/[/url] .

Диплом вуза купить официально с упрощенным обучением в Москве

Полезная информация как официально купить диплом о высшем образовании

Быстрая схема покупки диплома старого образца: что важно знать?

Легальная покупка диплома ПТУ с сокращенной программой обучения

Как быстро получить диплом магистра? Легальные способы

Всё, что нужно знать о покупке аттестата о среднем образовании

Приобретение школьного аттестата с официальным упрощенным обучением в Москве

Аттестат 11 класса купить официально с упрощенным обучением в Москве

Покупка диплома о среднем полном образовании: как избежать мошенничества?

Официальное получение диплома техникума с упрощенным обучением в Москве

Как не стать жертвой мошенников при покупке диплома о среднем полном образовании

Как избежать рисков при покупке диплома колледжа или ПТУ в России

Вопросы и ответы: можно ли быстро купить диплом старого образца?

Где и как купить диплом о высшем образовании без лишних рисков

Как не попасть впросак при покупке диплома колледжа или ПТУ в России

Приобретение диплома ПТУ с сокращенной программой обучения в Москве

Покупка школьного аттестата с упрощенной программой: что важно знать

Пошаговая инструкция по официальной покупке диплома о высшем образовании

Узнайте, где найти лучшие цены на стоматологию в Минске, приглашаем почитать.

Стоматология недорого цены на услуги [url=http://www.total-implant.ru]http://www.total-implant.ru[/url] .

Как приобрести диплом техникума с минимальными рисками

Приобретение диплома ПТУ с сокращенной программой обучения в Москве

Официальное получение диплома техникума с упрощенным обучением в Москве

Как правильно приобрести диплом колледжа или ПТУ в России, важные моменты

Всё, что нужно знать о покупке аттестата о среднем образовании без рисков

Парадокс, но купить диплом кандидата наук оказалось не так и сложно

Сколько стоит диплом высшего и среднего образования и как его получить?

Как официально купить аттестат 11 класса с упрощенным обучением в Москве

Сколько стоит диплом высшего и среднего образования и как его получить?

Приобретение диплома ПТУ с сокращенной программой обучения в Москве

Купить диплом магистра в Волгограде

Как приобрести диплом техникума с минимальными рисками

Официальная покупка школьного аттестата с упрощенным обучением в Москве

Как купить аттестат 11 класса с официальным упрощенным обучением в Москве

Как купить диплом о высшем образовании с минимальными рисками

Покупка диплома о среднем полном образовании: как избежать мошенничества?

Как быстро и легально купить аттестат 11 класса в Москве

Как приобрести диплом техникума и колледжа в Кирове?

Как купить аттестат 11 класса с официальным упрощенным обучением в Москве

Продуктивный инструмент для обработки горных пород с уникальной системой просеивания.

Барабанный грохот [url=https://barabaniy-grohot.moscow/]https://barabaniy-grohot.moscow/[/url] .

Как официально приобрести аттестат 11 класса с минимальными затратами времени

Быстрая схема покупки диплома старого образца: что важно знать?

Сколько стоит получить диплом высшего и среднего образования легально?

Процесс получения диплома стоматолога: реально ли это сделать быстро?

Легальная покупка школьного аттестата с упрощенной программой обучения

Полезная информация как купить диплом о высшем образовании без рисков

Можно ли быстро купить диплом старого образца и в чем подвох?

Как безопасно купить диплом колледжа или ПТУ в России, что важно знать

Быстрое обучение и получение диплома магистра – возможно ли это?

Официальная покупка школьного аттестата с упрощенным обучением в Москве

Покупка диплома о среднем полном образовании: как избежать мошенничества?

Пошаговая инструкция по официальной покупке диплома о высшем образовании

Купить диплом о среднем образовании в Москве и любом другом городе

Сколько стоит диплом высшего и среднего образования и как это происходит?

Как оказалось, купить диплом кандидата наук не так уж и сложно

Можно ли купить аттестат о среднем образовании, основные моменты и вопросы

Как официально приобрести аттестат 11 класса с минимальными затратами времени

Где и как купить диплом о высшем образовании без лишних рисков

Как быстро получить диплом магистра? Легальные способы

Аттестат школы купить официально с упрощенным обучением в Москве

Легальная покупка диплома ПТУ с сокращенной программой обучения

Как получить диплом техникума с упрощенным обучением в Москве официально

Официальная покупка аттестата о среднем образовании в Москве и других городах

Официальная покупка школьного аттестата с упрощенным обучением в Москве

Как официально купить диплом вуза с упрощенным обучением в Москве

Kra19.at

Всё, что нужно знать о покупке аттестата о среднем образовании

Как не попасть впросак при покупке диплома колледжа или ПТУ в России

Всё, что нужно знать о покупке аттестата о среднем образовании

Легальная покупка диплома о среднем образовании в Москве и регионах

Как приобрести аттестат о среднем образовании в Москве и других городах

Узнайте, как приобрести диплом о высшем образовании без рисков

Процесс получения диплома стоматолога: реально ли это сделать быстро?

Приобретение школьного аттестата с официальным упрощенным обучением в Москве

Узнайте, как приобрести диплом о высшем образовании без рисков

Сколько стоит диплом высшего и среднего образования и как его получить?

Как приобрести аттестат о среднем образовании в Москве и других городах

Всё, что нужно знать о покупке аттестата о среднем образовании без рисков

Пошаговая инструкция по официальной покупке диплома о высшем образовании

Как официально купить аттестат 11 класса с упрощенным обучением в Москве

Официальная покупка школьного аттестата с упрощенным обучением в Москве

Приобретение диплома ПТУ с сокращенной программой обучения в Москве

Узнайте, как приобрести диплом о высшем образовании без рисков

Процесс получения диплома стоматолога: реально ли это сделать быстро?

Как быстро и легально купить аттестат 11 класса в Москве

Купить диплом Нижний Новгород

Сколько стоит диплом высшего и среднего образования и как его получить?

Можно ли купить аттестат о среднем образовании, основные моменты и вопросы

Всё о покупке аттестата о среднем образовании: полезные советы

Можно ли купить аттестат о среднем образовании? Основные рекомендации

Покупка школьного аттестата с упрощенной программой: что важно знать

Всё, что нужно знать о покупке аттестата о среднем образовании

Легальная покупка диплома о среднем образовании в Москве и регионах

Всё о покупке аттестата о среднем образовании: полезные советы

Сколько стоит диплом высшего и среднего образования и как его получить?

Реально ли приобрести диплом стоматолога? Основные этапы

Быстрая схема покупки диплома старого образца: что важно знать?

Официальное получение диплома техникума с упрощенным обучением в Москве

Удивительно, но купить диплом кандидата наук оказалось не так сложно

Узнайте, как приобрести диплом о высшем образовании без рисков

Приобретение школьного аттестата с официальным упрощенным обучением в Москве

Официальная покупка диплома вуза с сокращенной программой в Москве

Как правильно купить диплом колледжа и ВУЗа в России, подводные камни

Сколько стоит диплом высшего и среднего образования и как его получить?

Полезные советы по безопасной покупке диплома о высшем образовании

Рекомендации по безопасной покупке диплома о высшем образовании

Удивительно, но купить диплом кандидата наук оказалось не так сложно

Как оказалось, купить диплом кандидата наук не так уж и сложно

Узнайте, как безопасно купить диплом о высшем образовании

Как приобрести диплом техникума с минимальными рисками

Приобретение диплома ПТУ с сокращенной программой обучения в Москве

Диплом вуза купить официально с упрощенным обучением в Москве

Как правильно приобрести диплом колледжа или ПТУ в России, важные моменты

Диплом техникума купить официально с упрощенным обучением в Москве

Быстрая схема покупки диплома старого образца: что важно знать?

Полезные советы по безопасной покупке диплома о высшем образовании

Обращаясь к нашему списку МФО, вы можете быть уверены в положительном решении. [url=https://mikro-zaim-online.ru/]взять займ без отказа онлайн на карту[/url] доступен всем, без исключений, на сумму от 1 до 30 тысяч рублей.

Аттестат 11 класса купить официально с упрощенным обучением в Москве

Узнайте, как безопасно купить диплом о высшем образовании

Как не стать жертвой мошенников при покупке диплома о среднем полном образовании

[url=https://xn—–7kcgpnpy3bral5h.xn--p1ai/]Все-займы-тут.рф[/url] — это платформа, где собраны МФО, выдающие микрокредиты всем от 18 лет. Более 40 компаний предлагают займы до 30 тысяч рублей, оформление производится по паспорту без проверок. Простой и удобный процесс.

Процесс получения диплома стоматолога: реально ли это сделать быстро?

Сколько стоит диплом высшего и среднего образования и как его получить?

Официальная покупка диплома вуза с сокращенной программой в Москве

Пошаговая инструкция по безопасной покупке диплома о высшем образовании

Официальная покупка диплома вуза с сокращенной программой обучения в Москве

Как безопасно купить диплом колледжа или ПТУ в России, что важно знать

Получите займ на карту без отказа за 5 минут! Оформление онлайн, возраст с 18 лет. Требуется только паспорт. До 30 000 рублей на вашу карту без проверок и звонков.

Официальная покупка аттестата о среднем образовании в Москве и других городах

Возможно ли купить диплом стоматолога, и как это происходит

Как официально купить диплом вуза с упрощенным обучением в Москве

Как купить аттестат 11 класса с официальным упрощенным обучением в Москве

Пошаговая инструкция по безопасной покупке диплома о высшем образовании

Реально ли приобрести диплом стоматолога? Основные этапы

Диплом вуза купить официально с упрощенным обучением в Москве

Аттестат 11 класса купить официально с упрощенным обучением в Москве

Полезные советы по безопасной покупке диплома о высшем образовании

Парадокс, но купить диплом кандидата наук оказалось не так и сложно

дубай катание на лодке arenda-yahty-dubai.ru

отели екатеринбурга в центре

Пошаговая инструкция по официальной покупке диплома о высшем образовании

Узнайте стоимость диплома высшего и среднего образования и процесс получения

Как приобрести аттестат о среднем образовании в Москве и других городах

Аттестат 11 класса купить официально с упрощенным обучением в Москве

сантехника онлайн купить каталог

Мы собрали для вас важные темы для пользователей Казахстана с подробными объяснениями: https://belspr.ru/pryamie-translyatsii-sportivnih-sobitiy/eva-elfi-1xbet.php. Активация промокодов на этапе создания профиля и на начальном пополнении баланса помогает существенно увеличить сумму на счёте и начать игру с дополнительными преимуществами

Стоимость дипломов высшего и среднего образования и как избежать подделок

Корпоративная электронная почта — это система обмена сообщениями, разработанная для использования организациями и компаниями, которая обеспечивает профессиональную коммуникацию между сотрудниками, клиентами и партнерами. Она включает в себя доменное имя, связанное с компанией, что придает адресам электронной почты официальный вид (например, имя@компания.ru). Подробнее по ссылке https://korp-pochta.ru/

Уборка промышленных помещений СПб https://chistka-prom-pomeshchenij-spb.ru/

Клининг по уборке паркинга https://chistka-parkinga-spb-lo.ru/

Интернет-магазин инструментов https://profimaster58.ru для работы по металлу — ваш эксперт в качественном оборудовании! В ассортименте: измерительный инструмент, резцы, сверла, фрезы, пилы и многое другое. Гарантия точности, надежности и выгодных цен.

Смотрите аниме онлайн https://studiobanda.net бесплатно и без рекламы. Удобный каталог с популярными тайтлами, новинками и свежими сериями. Высокое качество видео и быстрый плеер обеспечат комфортный просмотр. Подборки по жанрам, рекомендации и регулярные обновления сделают ваш опыт максимально приятным.

лучшие школы фигурного катания записаться в клуб по фигурному катанию

голая шурыгина https://shuriginadiana.org

Официальная покупка аттестата о среднем образовании в Москве и других городах

Приобретение школьного аттестата с официальным упрощенным обучением в Москве

Приобретение диплома ПТУ с сокращенной программой обучения в Москве

Можно ли купить аттестат о среднем образовании? Основные рекомендации

Предприниматель и инвестор Святослав Гусев https://www.twitch.tv/gusevtv специализирующийся на IT, блокчейн-технологиях и венчурном инвестировании. Активно делится аналитикой рынка, инсайдами и новостями, которые помогут заработать каждому!

Купить диплом магистра оказалось возможно, быстрое обучение и диплом на руки

Вопросы и ответы: можно ли быстро купить диплом старого образца?

Реально ли приобрести диплом стоматолога? Основные этапы

Быстрая покупка диплома старого образца: возможные риски

Купить диплом о среднем полном образовании, в чем подвох и как избежать обмана?

Полезная информация как купить диплом о высшем образовании без рисков

Официальная покупка диплома ПТУ с упрощенной программой обучения

Покупка диплома о среднем полном образовании: как избежать мошенничества?

Полезные советы по безопасной покупке диплома о высшем образовании

Как избежать рисков при покупке диплома колледжа или ПТУ в России

Как приобрести диплом о среднем образовании в Москве и других городах

Как не попасть впросак при покупке диплома колледжа или ПТУ в России

Надежный источник для заказа качественных товаров уже доступен. Подробности по ссылке: https://pr-hot1.ru/

купить диплом в сыктывкаре prema-diploms.ru .

Официальная покупка диплома вуза с сокращенной программой обучения в Москве

Kasyno Vavada to młode kasyno, które posiada starannie opracowaną platformę, oferującą szeroki wybór automatów do gry od wiodących dostawców. Platforma działa na specjalistycznym rynku od 2017 roku i skierowana jest do graczy z Poland, Ukrainy i innych krajów. Vavada Casino działa legalnie https://vavadas.pl/

смотреть фильмы бесплатно ужасы фильмы 2024 смотреть онлайн в HD

лучшие фильмы онлайн в США фильмы 2024 смотреть онлайн с переводом

Nowe Online Kasyna z Darmowymi Spinami Bez Depozytu. Program bonusowy każdego nowego kasyna online w Polsce obejmuje różnorodne promocje. Użytkownicy mogą je aktywować podczas rejestracji. Są to bonusy pieniężne i darmowe spiny. Pierwsze z nich gracze mogą wydawać według własnego uznania. Drugie, darmowe spiny bez depozytu, można wykorzystać w określonych slotach https://kasynadarmowespiny.pl/

Официальная покупка диплома вуза с упрощенной программой обучения

купить диплом металлурга [url=https://2orik-diploms.ru/]2orik-diploms.ru[/url] .

фільми онлайн безкоштовно детективи дивитися кіно онлайн детективи

Если вы столкнулись с неожиданными расходами, все займы поможет быстро решить проблему. Забудьте о строгих требованиях банков и отказах из-за кредитной истории. Сегодня получить займ можно буквально за несколько кликов. Все, что нужно — это заполнить анкету, дождаться одобрения и получить деньги прямо на карту. Такой сервис создан для тех, кто ценит оперативность и комфорт в финансовых вопросах.

где купить диплом медсестры prema-diploms.ru .

Официальная покупка диплома вуза с упрощенной программой обучения

сделать диплом о высшем образовании [url=https://2orik-diploms.ru/]сделать диплом о высшем образовании[/url] .

https://receptosbook.su/ – всегда найдёте массу идей не только для закусок, но и что приготовить в качестве первого блюда (супы), второго, а также завтраки, салаты.

купить диплом автошколы prema-diploms.ru .

At Cheap SEO Solutions https://cheap-seo-solutions.com we don’t believe in half-measures. We deliver comprehensive SEO solutions that cover all the bases, from keyword research and on-page optimization to link building and content creation. Our goal is to help businesses improve their search engine rankings, drive organic traffic, and increase conversions.

Ставки на спорт с Vavada https://selfiedumps.com это простота, надежность и высокие шансы на победу. Удобная платформа, разнообразие событий и быстрые выплаты делают Vavada идеальным выбором для любителей азарта. Зарегистрируйтесь сейчас и начните выигрывать вместе с нами!

Discover the power of AI with deepnudenow Fast image processing and accessible functionality allow you to create unique effects. Enjoy safe and anonymous use of the platform for entertainment.

Мы подготовили для вас популярные вопросы для казахстанских пользователей и дополнили их ответами: Как погасить аванс в 1xbet. Ввод промокодов при регистрации аккаунта и во время начального депозита обеспечивает возможность существенно увеличить баланс и начать игру с преимуществом.

free comic book reader drama free comic book reader in France

best manga reading site in HD manga reader app fantasy

Когда каждая минута на счету, займы онлайн без проверки кредитной истории и отказов становится настоящим спасением. Не нужно собирать стопки документов или ждать решения банка неделями. Просто заполните анкету онлайн, и деньги окажутся на вашей карте практически мгновенно. Удобство такого способа заключается в минимуме формальностей и высокой вероятности одобрения. Этот вариант особенно популярен среди тех, кто ценит свое время и не готов тратить его на долгие ожидания.

Легальная покупка диплома ПТУ с сокращенной программой обучения

1win aviator para yat?rma casino bonus 1win

Emerald apartment Montenegro property sales

Проявление эмпатии https://empatiya-intellekt.ru/

skachat mostbet mostbet бонусы при регистрации

mostbet слоты mostbet kg скачать

Montenegro wohnung kaufen Montenegro immobilien kaufen

новинки кино онлайн в СНГ лучшие фильмы онлайн боевики

kolasin Montenegro immobilien in Montenegro

смотреть фильмы онлайн в Казахстане новинки кино онлайн детективы

Мы подготовили специально для вас частые вопросы для жителей Казахстана с подробными объяснениями: https://mp3hiton.ru/. Ввод бонусных кодов при создании аккаунта и при первом пополнении счёта помогает повысить баланс для игры и улучшить стартовые условия

Смотрите любимые дорамы https://dorama2025.ru онлайн в HD-качестве! Огромный выбор корейских, китайских, японских и тайваньских сериалов с профессиональной озвучкой и субтитрами.

diyet planlar? v? tovsiy?l?r g?nc? hava proqnozu

новая манхва читать онлайн приключения лучшие манхвы читать 2025

1win android 1win кыргызстан

hotel Montenegro bar immobilien Montenegro

amendments company formation in Montenegro

teleprompter for phone teleprompter online

Останні новини Черкас https://18000.ck.ua та Черкаської області. Важливі новини про політику, бізнес, спорт, корупцію у владі на сайті 18000 ck.ua.

манхва на русском языке детектив лучшие манхвы читать 2018

Sveti stefan immobilien in Montenegro

видеоаналитика распознавание vms для видеонаблюдения

https://www.clocksforlife.com/clocks-for-fireplace-mantel/

Ищете качественные стероиды для мужчин? У нас вы найдете широкий выбор сертифицированной продукции для набора массы, сушки и улучшения спортивных результатов. Только проверенные бренды, доступные цены и быстрая доставка. Ваше здоровье и успех в спорте – наш приоритет! Заказывайте прямо сейчас!”

онлайн ридер манхвы в Казахстане новинки бесплатно читать манхву онлайн

фільми 2011 дивитися онлайн фільми 2006 дивитися онлайн

дивитися кіно онлайн на планшеті дивитися кіно онлайн на телефоні

кращі фільми онлайн комедії дивитися кіно онлайн в Канаді

clock for your fireplace mantel

список мфо онлайн без отказа МФО

praha 420 thc joint in prague

шурыгина порно диана шурыгина фото

новинки кино онлайн фантастика смотреть фильмы бесплатно боевики

лучшие фильмы 2025 смотреть онлайн фильмы 2010 смотреть онлайн

Witamy w Slotico! Tutaj znajdziesz unikalną kolekcję kasyn online. Slottica PL oferuje setki gier, od klasycznych automatów do gier po nowoczesne automaty wideo i ekscytujące gry stickman na żywo.

Строительный портал https://bastet.com.ua ваш путеводитель в мире стройки! Подборка лучших материалов, контакты мастеров, проекты и лайфхаки. Создавайте уют и красоту с нашим сервисом!

Нужны деньги срочно Веб Займ – ваш быстрый выход! Подайте заявку из любого места, получите деньги в течение нескольких минут. Удобно, прозрачно, без скрытых комиссий.

Финансовые трудности? Решите их за минуты быстроденьги займ на карту мгновенно с моментальным переводом на карту. Оформление онлайн, простые условия и никакого лишнего стресса. Ваш надежный финансовый помощник!

Biography of Spanish footballer Pedri https://pedri-bd.com statistics at Barcelona, ??games with teammate Gavi, inclusion in the national team for Euro, meme with Cristiano Ronaldo.

Biography of Argentine footballer Paulo Dybala https://paulo-dybala-bd.com personal life, tattoos on the body, wedding with his wife Oriana Sabatini.

Biography of Argentine footballer Paulo Dybala https://paulo-dybala-bd.com personal life, tattoos on the body, wedding with his wife Oriana Sabatini.

Biography of Dutch footballer https://xavi-simons-bd.com midfielder for Paris Saint-Germain and the Netherlands national team Xavi Simons. Sports career, playing for RB Leipzig and Barcelona, ??participation in Euro 2024, achievements. Personal life, girlfriend, latest news in 2024.

Team Spirit – 2024 roster team-spirit-dota2.com news, match and tournament schedule, statistics, award list, rating, logo.

Execration is a legendary Dota 2 execration-dota2.com/ eSports team that conquers the heights of world eSports with its skill and tactics.

Строительный и архитектурный портал https://intertools.com.ua все самое интересное о строительстве и архитектуре – новости архитектуры и строительства, обзоры и аналитика.

The legendary Dota 2 team team heroic dota2 Team Heroic. Multiple champions and fan favorites. Virtuoso play and exciting matches.

Приобретение школьного аттестата с официальным упрощенным обучением в Москве

Диплом техникума купить официально с упрощенным обучением в Москве

Welcome to the main page of the fan site karim-benzema-english dedicated to the world football star – Karim Benzema. Find out everything about his incredible career, incredible achievements and phenomenal skills. Get the latest news, photos and interesting facts about this talented striker. Dive into the exciting world of football with Karim Benzema!

Welcome to the ultimate Thibaut Courtois https://thibaut-courtois-english.com fan site, celebrating the brilliance of the world-class goalkeeper. Discover his accolades, career highlights and more!

Official KT Rolster website kt-rolster-league-of-legends com news, matches, tournaments, player statistics and LOL Betting analytics! Support the team!

Official website dsyre valorant of the Dsyre team: news, matches, tournaments, player statistics and Valorant Betting. Support us!

Biography of footballer Zlatan Ibrahimovic zlatan-ibrahimovic-bd.com personal life, his wife Helena Seger, the birth of his sons and rumors of the forward’s infidelity with Diletta Leotta. Club career and playing for the Swedish national team, the athlete’s goals and achievements, his return to FC Milan.

Biography of Norwegian footballer Erling Haaland erling-haaland-bd.com/ photo of the striker of the Manchester City club and the Norwegian national team, sports career in football clubs Borussia Dortmund and Red Bull Salzburg, height, achievements.

Karim Benzema biography karim-benzema-bd com personal life, scandalous reputation due to a relationship with a minor and other problems with the law.

Biography of French footballer Ousmane Dembele ousmane-dembele-bd.com personal life, mother’s name, wedding with his wife, religious beliefs.

Elephant is one of the strongest eSports teams elephant dota2 com in Dota 2, having won many prestigious trophies thanks to well-coordinated team play, brilliant drafts and the skill of each player.

Latest news https://leagueoflegends-esports.com match results and eSports analytics on one portal – “League of Legends”!

Discover the world of Apeks http://apeks-valorant.com news, matches, player statistics and Valorant Betting. Follow the team and bet wisely!

JD Gaming jd gaming league of legends is one of the greatest teams in LoL history. The site features news, matches, player statistics and betting.

Explore the journey of Astralis astralis-counter-strike2 com the iconic esports team dominating CS2. Known for innovation, teamwork, and success, they inspire players worldwide and set new standards in competitive gaming.

Learn about the Paper Rex team https://paper-rex-valorant.com news, matches, player stats and Valorant betting tips!

Explore Team Liquid’s journey in CS2 team-liquid-counter-strike2 from groundbreaking strategies to top-tier talent development. Discover how this iconic team shapes the future of competitive Counter-Strike 2.

Biography of football player Cristiano Ronaldo http://cristiano-ronaldo-bd.com personal life, relationship with Irina Shayk, common-law wife Georgina Rodriguez, children.

Biography of footballer Mohamed Salah http://mohamed-salah-bd.com wife Maga Sadiq, children. Book “The Last Pharaoh”. Charity and good deeds. Statistics, salary and awards of the midfielder in Liverpool and the Egyptian national team in 2021.

Biography of football player David de Gea david-de-gea-bd.com/ personal life, height, girlfriend. Goalkeeper statistics at the 2018 World Cup, salary at Manchester United, career at Atletico Madrid. Latest news in 2024.

Harry Kane biography http://harry-kane-bd.com personal life, wife and children. The footballer’s club career, his salary and statistics, contract with Tottenham Hotspur. Playing for the England national team, captain’s role at the 2022 World Cup.

Invictus Gaming is a legendary invictus-gaming-dota2.com/ esports organization known for its remarkable victories in Dota 2, including the championship at The International 2018.

Latest news http://league-of-legends-esports.com analytics and forecasts in the world of League of Legends eSports. Stay up to date with all the main events of the professional scene!

Official website t1-league-of-legends of the legendary eSports team T1 for League of Legends. Latest news, match results, player statistics and LOL Betting.

Latest news and analytics on League of Legends lol news com matches, tournaments, betting. Stay up to date with the latest eSports events!

Official website of the T1 t1 lol League of Legends eSports team. Latest news, matches, statistics, tournaments and predictions on LoL Betting.

Official website of the award-winning samsung-galaxy-league-of-legends.com Samsung Galaxy League of Legends team. Latest news, matches, statistics, player profiles and bets on games.

Fnatic is a legendary League fnatic-league-of-legends.com/ of Legends eSports team. Our website has all the latest news, matches, player statistics and game predictions.

Official Team Liquid website team-liquid-league-of-legends latest news, match results, tournaments, player profiles and LOL Betting.

security camera recording software ip camera software for pc

Find out everything about Team WE team-we-league-of-legends com news, matches, player statistics and bets on League of Legends. Support the team!

Valorant Esports valorant-esports-en.com News, matches, tournaments, awards, game news

Follow Gen.G Esports geng esports news, matches, tournaments, player stats and betting analytics on Valorant!

Enter the world of Team Falcons https://team-falcons-valorant.com news, matches, player stats and bets on Valorant. Stay up to date!

hashish delivery in prague https://online24.site

cannafood in prague marijuana delivery in prague

cannafood for sale in prague weed in prague

buy thc vape in prague buy thc vape in prague

Официальная покупка школьного аттестата с упрощенным обучением в Москве

buy thc gummies in prague marijuana in prague

buy hashish in prague https://shopraha.site

hashish in prague thc gummies delivery in prague

thc joint delivery in prague thc chocolate for sale in prague

buy thc joint in prague cali weed in prague

Как избежать рисков при покупке диплома колледжа или ПТУ в России

Find out the latest news sentinels valorant com matches and statistics of the Sentinels Valorant team. Betting and analytics are waiting for you!

Virtus.pro is a professional eSports team virtus-pro with a rich history. Known for victories in CS:GO and striving for the top in CS2. Find out about the strategy, roster and future of this legend.

Explore Natus Vincere natus-vincere the legendary esports organization excelling in CS2 and beyond. With a legacy of victories and innovative strategies, NAVI inspires millions and defines esports greatness.

Discover the journey of MOUZ mouz-counter-strike2 a powerhouse in CS2 esports. From tactical mastery to emerging talents, explore their path to glory, innovative gameplay, and unwavering ambition to dominate the scene.

Biography of football player Luis Alberto Suarez luis-suarez-bd.com personal life, daughter, wife, children, height. Leaving the club Atletico Madrid, career in Barcelona and Liverpool, goal statistics.

Biography of football player Neymar neymar-bd.com personal life, relationships and rumors of romances with Katya Safarova, Natalia Barulich, the birth of a son and Bruna’s last girlfriend, the birth of daughters.

Biography of football player Jude Bellingham https://jude-bellingham-bd.com personal life, relationship with girlfriend Laura. Player statistics in the Real Madrid team, matches for the England national team with Harry Kane, the athlete’s salary, conflict with Mason Greenwood.

Biography of footballer Kylian Mbappe kylian mbappe personal life, rumors of an affair with Alicia Aylis and Ines Rau. Career, statistics and salary at Paris Saint-Germain, victory at the World Cup and other achievements of the striker.

Biography of Belgian footballer kevin de bruyne bd com Kevin De Bruyne (Kevin De Bruyne): personal life, relationship with his wife, conflict with Thibaut Courtois over his girlfriend Caroline.

Biography of football player Antoine Griezmann https://antoine-griezmann-bd.com personal life, birth of children, national origin. Career now, games for the club Atletico Madrid, striker of the French national team at the European Championship, statistics of matches in the Barcelona team.

Biography of football player Luka Modric luka-modric personal life, height, wife Vanja Bosnic, book “Autobiography”, age. Career at Real Madrid, receiving the Golden Ball, assists, performance at Euro 2024.

Biography of footballer Paul Pogba https://paul-pogba-bd.com personal life, his wife and children, conversion to Islam. Footballer’s career at Manchester United and other clubs, playing for the French national team.

Biography of footballer Toni Kroos toni kroos personal life, relationship with his wife. Announcement of retirement after the Euro, tattoos on his hands. Achievements in the Real Madrid club and the German national team, goals scored, passes made and statistics. Winning trophies. Latest news in 2024.

Покупка школьного аттестата с упрощенной программой: что важно знать

Biography of Belgian footballer Kevin De Bruyne kevin de bruyne az com (Kevin De Bruyne): personal life, relationship with his wife, conflict with Thibaut Courtois over girlfriend Caroline.

Biography of football player Jude Bellingham jude bellingham az com personal life, relationship with girlfriend Laura. Statistics of the player in the Real Madrid team, matches of the England national team with Harry Kane, the athlete’s salary, conflict with Mason Greenwood.

Biography of football player Toni Kroos toni-kroos-az.com personal life, relationship with his wife. Announcement of retirement after the Euro, tattoos on his arms.

Biography of French footballer Ousmane Dembele https://ousmane-dembele-az.com personal life, mother’s name, wedding with his wife, religious beliefs. Career development, matches with Kylian Mbappe

Biography of Senegalese footballer Sadio Mane sadio-mane-az.com personal life, charity work. Success story of the Senegalese athlete playing for the national team, career at Liverpool and Bayern.

Karim Benzema’s biography karim benzema az com personal life, scandals, marriage to Cora Gautier, son Ibrahim, divorce, new girlfriend Jordan Ozuna and career at Real Madrid.

Try your luck and win fun https://gates-of-olympus.com.az prizes by playing Gates of Olympus™ slot from Pragmatic Play for free!

Olivier Giroud’s https://olivier-giroud-az.com biography: personal life, wife Jennifer, career at Chelsea, Arsenal and Milan, records and news for France 2024.

Biography of football player khvicha-kvaratskhelia-az com Khvicha Kvaratskheliya: family, career at Dynamo, Lokomotiv, Napoli, success in the Georgian national team.

Book of Oz book-of-oz.com.az/ is a book slot from Triple Edge Studios in partnership with Microgaming.

Покупка школьного аттестата с упрощенной программой: что важно знать

Hot Fruits 100 Slot https://hot-fruits-100.com.az Review by Amatic Industries – Play Hot Fruits 100 demo for free or real money. Bonuses and best casinos for September 2024!

Learn everything about blackjack https://blackjack.com.az rules, types of bets, features of the online game and answers to popular questions.

JetX is a unique simulation game https://jetx.com.az from SmartSoft Gaming. Players fly a virtual plane and collect their winnings safely.

Try the free demo game Crazy Monkey crazy monkey (Igrosoft) and read our exclusive review!

Discover Space XY space xy Take advantage of bonuses and free play to increase your chances of winning!

Bayer 04 Football Club bayer 04 composition, statistics, best Bayer players

RB Leipzig rb leipzig com az team history, club titles, top scorers and players in team history

Phil Foden http://phil-foden-az.com is a talented midfielder for Manchester City. Find out about his biography, statistics and latest news.

Declan Rice (Arsenal) declan-rice-az.com/ midfielder, 25 years old. Check out his biography, statistics, goals and latest 2024 news.

Current Heidenheim fc-heidenheim.com az squad with player stats and market value, match schedule, club news and rumours

https://cable-invest.ru/

Yassin Bunu from Al-Hilal yassine-bounou-az com biography, statistics, news and everything about his career in football.

Learn about Garrett Bale http://gareth-bale-az.com his biography, personal life, achievements and the latest news from the world of football.

Thiago Silva http://thiago-silva-az.com is a legendary defender for Chelsea and the Brazilian national team. On the site you can find a biography, the latest news, statistics, videos and interviews. Learn everything about the career and achievements of the great football player.

Everything about Moussa Dembele moussadembele-az.com biography, goals, news, statistics and photos. Follow the career of the Al-Ittihad star with us!

Everything about Marquinhos marquinhos-az.com/ biography, news, matches, statistics, photos and videos of the best moments. Learn everything about the legendary footballer!

Atletico Madrid atletico-madrid-az.com/ is a symbol of passion, resilience and struggle. A club with a rich history, loyal fans and a fighting spirit that inspires both on and off the pitch. Never give up!

Bukalo Saka bukayo saka is one of the brightest and most promising footballers of his generation. His incredible skill, tactical awareness and strong performance on the pitch have already earned him recognition at Arsenal and the England national team.

Kevin De Bruyne kevin-de-bruyne.com.az/ is a Belgian footballer and Manchester City star. He is known for his superior skills, accurate passing and leadership. Kevin is a key member of the Belgium national team and has won multiple titles.

George Best http://george-best.com.az is a brilliant footballer and a shining symbol of the 1960s, known for his talent and turbulent life. He left an indelible mark on football by combining success on the pitch with the tragedy of personal struggle.

Rudy Gobert rudy-gobert-az.com is a French center and one of the best defenders in the NBA, nicknamed “The French Tower.” A three-time Defensive Player of the Year, he inspires with his skills and commitment to excellence.

Luka Doncic https://lukadoncic-az.com is a Slovenian basketball player, the leader of the Dallas Mavericks team and one of the main stars of the NBA. His unique playing style, records and influence have made him a symbol of European success in world basketball.

Giannis Antetokounmpo http://giannis-antetokounmpo-az.com is an NBA legend known as the “Greek Freak.” His journey from poverty in Athens to a championship with the Milwaukee Bucks has inspired millions. Hard work, family, and leadership are his core values.

Jayson Tatum jayson tatum az com is one of the NBA’s most exciting and versatile players, a leader for the Boston Celtics and an inspiration to millions. Learn all about his path to success, his personal life, his style and the legacy he has created both on and off the court.

Shai Gilgeous-Alexander shay-gilgeous-alexander is a talented NBA basketball player and the leader of the Oklahoma City Thunder. He is known for his versatility, leadership, and contributions to the Canadian team. He is a style icon and an inspiration to his fans.

Joel Embiid joel-embiid-az com is an NBA star, leader of the Philadelphia 76ers, and the first Cameroonian MVP. His journey from the streets of Cameroon to the basketball Olympus is inspiring, and his charisma and talent captivate millions.

Kevin Durant kevin durant az com is an NBA star known for his versatility, work ethic, and skill. A four-time league leading scorer, two-time Finals MVP, and three-time Olympic champion. A living legend of basketball.

Anthony Edwards anthony-edwards is a star for the Minnesota Timberwolves, a charismatic leader, and a key player in the NBA. His story of overcoming adversity, strong play, and contributions beyond basketball inspires millions.

Jalen Brunson jaylen bronson is one of the hardest working and smartest players in the NBA. He is the leader of the New York Knicks, a two-time NCAA champion, and an inspiration to young athletes. His game and personality are inspiring.

Devin Booker devin booker is an NBA star, leader of the Phoenix Suns, record-breaker, and master of accurate shots. His path to success is inspiring: from high school talent to superstar, he has become an example of hard work and dedication to the sport.

De’Aaron Fox https://deaaron-fox-az.com is a point guard for the Sacramento Kings known for his speed, leadership, and clutch play. He is an inspiration on and off the court, actively involved in charity work and family life.

Trae Young trae-young-az.com is one of the most exciting point guards in the NBA. Known for his long-range shooting ability and high basketball IQ, the Atlanta Hawks leader inspires millions of fans with his style and charisma.

Kyrie Irving is an NBA star https://kyrieirving-az.com champion, dribbler, and leader on the court. His accomplishments, philanthropy, and bold vision make him one of the most colorful and controversial figures in sports.

Ja Morant ja-morant is a talented basketball player known for his rapid rise to fame as the leader of the Memphis Grizzlies in the NBA. He is known for his legendary performance on the court and his support for young people off the court.

Learn about the life and career of Damian Lillard damien-lillard-az.com a basketball player, musician, and activist whose impact transcends sports, inspiring millions around the world.

Anthony Davis https://anthony-davis-az.com is an NBA star, a champion, a master of defense and offense. His versatility and leadership inspire a new generation of basketball players and change the standard for big men in the game.

Julius Randle is a versatile NBA forward julius randle az com a leader for the Knicks, and an inspiring example of perseverance. His play, leadership, and desire to win make him one of the defining figures in the modern league.

Cristiano Ronaldo biography cristiano ronaldo personal life, relationships with Irina Shayk and Georgina Rodriguez, children, career at Real and Juventus, records with Portugal at Euro 2020.

Biography of footballer Luis Alberto Suarez luis-suarez-az.org personal life, wife, children, height. Departure from Atletico Madrid, career at Barcelona and Liverpool, goal statistics. Playing for Gremio, moving to Inter Miami, retirement from international duty and the latest news in 2024.

Biography of footballer Mohamed Salah http://mohamed-salah-az.org wife Magi Sadiq, children, charity work, book “The Last Pharaoh”. Statistics, salary and awards with Liverpool and Egypt in 2024.

Born to a British-Nigerian jamal-musiala-az.org/ father and a German mother of Polish descent, young Jamal explores cultural differences while playing for Germany at the Euros, facing off against Jude Bellingham. Breaking news 2024.

Talented Nigerian striker Victor Osimhen https://victor-osimhen-az.com proudly represents Italian club Napoli and the Nigerian national team. This story highlights his remarkable sporting career, personal development and notable achievements, including a loan spell at Galatasaray.

Federico Valverde’s http://federico-valverde-az.org biography: personal life, date of birth, children with Mina Bonino, salary, religion, playing style on the pitch, Real Madrid statistics, salary, number inherited from Kroos, position for 2024 and news.

Biography of Spanish footballer Rodri https://rodri-az.org Manchester City midfielder, salary, worth, religion, Euro match statistics, champion status and games with Joao Cancelo. Latest updates in 2024.

Spanish footballer and Athletic Bilbao http://nico-williams-az.org midfielder Nico Williams has had a remarkable career. He shares a close relationship with his brother Inaki. Recent reports have included a potential move to Barcelona in 2024.

Biography of Lamine Yamal lamine-yamal-az.com a Spanish winger who plays for FC Barcelona and the national team. Includes career highlights, statistics, Euro 2024 winning salary and personal life.

Biography of LeBron James bronny-james-az.org son Bronny James. Covers his personal life, family, health issues, NBA draft, and the latest news in 2024.

Frankie de Jong’s biography frenkie de jong az org covers his personal life, height, wife, club stats at Barcelona and Ajax, transfer rumours to Man Utd, playing position and shirt number.

Magic Johnson’s biography magic johnson az com photos, news, personal life, basketball career, religion, prison, statistics, rivalry with Michael Jordan and his fight against AIDS.

Luka Doncic biography http://luka-doncic-az.com salary, signature shoes, stats, NBA comparisons with Trae Young, games with Jokic and Irving, personal life updates.

Stephen Curry stephen-curry-az.com/ biography: personal life, height, weight, career, team, injuries, three-pointers, LeBron James, statistics, sneakers and 2024 updates.

Портал для строительства https://6may.org и ремонта: полезные советы, современные материалы, проекты и идеи. Все, что нужно для воплощения ваших задумок – от фундамента до крыши.

Портал о строительстве https://aziatransbud.com.ua статьи, видео, инструкции, каталоги материалов и инструментов. Советы для дома и бизнеса. Легко строить, удобно ремонтировать!

Всё для строительства и ремонта https://artpaint.com.ua на одном портале: советы экспертов, обзоры материалов, расчет сметы и готовые решения для вашего дома или бизнеса.

Все об озеленении и благоустройстве https://bathen.rv.ua Ландшафтный дизайн, проекты садов, террас и парков. Идеи для создания зеленых зон, подбор растений и профессиональные услуги для вашего участка.

Покер — это уже не просто игра, а наука. Покер помощь позволяет игрокам не только улучшать свои навыки, но и сокращать риск поражений. Новые технологии открывают перед каждым игроком широкие возможности.

Разработка и продвижение сайтов https://magikfox.ru в Москве и регионах России от диджитал агентства MagicFox. Лучшие цены на рускрутку. Сделаем продающий сайт на Битрикс и обеспечим высокий уровень продаж.

бодибилдинг стероиды купить стероиды купить магазин

пневмозаглушки для трубопроводов купить трубные пневмозаглушки

Профессиональный портал для строительства https://blogcamp.com.ua проекты, материалы, расчеты, советы и вдохновение. Все, чтобы ваш ремонт или стройка были успешными.

Хотите построить дом https://donbass.org.ua или сделать ремонт? Здесь вы найдете всё: инструкции, идеи, современные технологии и проверенные решения. Портал для тех, кто строит.

Делайте ремонт https://esi.com.ua и стройте легко! Лучшие советы мастеров, подбор инструментов, инструкции и сметы. Мы поможем справиться с любой задачей.

Станьте мастером https://fmsu.org.ua своего дела! Портал для тех, кто хочет строить и ремонтировать качественно и выгодно.

Создайте дом своей мечты https://intellectronics.com.ua На нашем портале вы найдете идеи, инструкции и новейшие технологии для ремонта и строительства.

Все для строителей и мастеров https://dki.org.ua актуальные технологии, практические советы, строительные материалы и проекты. Простые решения для сложных задач!

para kazandД±ran sohbet siteleri http://sweetbonanza25.com/# sweet bonanza oyna

tГјrkiye casino siteleri

Архитектура и дизайн интерьера https://it-cifra.com.ua под ключ: современные решения, индивидуальный подход и гармония стиля и функциональности. Создаем пространство вашей мечты!

Найдите все для ремонта https://keravin.com.ua и строительства! Уникальные идеи, пошаговые инструкции и рекомендации специалистов на одном портале.

Мы помогаем строить https://juglans.com.ua лучше! Советы, проекты, новейшие материалы и технологии для вашего ремонта или строительства.

Ландшафтный дизайн https://kinoranok.org.ua и благоустройство для дома, офиса или парка. Профессиональные советы, подбор растений и реализация уникальных зеленых проектов.

Стройте с комфортом https://mr.org.ua полезные советы, новейшие технологии, пошаговые инструкции и проекты – всё для вашего удобства.

купить диплом о среднем образовании

Все секреты https://mramor.net.ua строительства в одном месте! Советы экспертов, подбор материалов и готовые проекты для вдохновения.

Решили строить или делать ремонт https://msc.com.ua Мы подскажем, как выбрать лучшие материалы, спланировать бюджет и воплотить все задумки.

Ваш путеводитель в мире строительства https://mtbo.org.ua полезные рекомендации, готовые проекты и современные решения для любых задач.

Всё для успешного строительства https://newboard-store.com.ua и ремонта на одном портале! Мы собрали актуальную информацию, идеи и инструкции для вашего удобства. Заходите и стройте с нами!

Информация о стройке https://purr.org.ua без лишних сложностей! Наш портал поможет выбрать материалы, узнать о технологиях и сделать ваш проект лучше.

for retail stores company registration in Montenegro

Ваш путеводитель в строительстве https://quickstudio.com.ua Ищите материалы, технологии или советы – всё это есть на нашем портале. Стройте с комфортом!

1win sign up 1win app

1win aviator predictor 1win uganda

Хочешь выигрывать в Холдеме, как профи? Подсказки для выигрыша в покере Холдем изменили мою игру. Теперь я забираю банк за банком. Последний вечер принес 8 000 рублей!

топаз натуральный камень https://topaztreasures.ru/

Вавада предлагает ставки на спорт Вавада на любой вкус! Здесь вы найдете ставки на футбол, теннис, баскетбол, киберспорт и многое другое. Широкий выбор событий, удобный интерфейс и выгодные коэффициенты делают платформу идеальной как для новичков, так и для опытных игроков. Начните свой путь в ставках уже сегодня!

Всё, что нужно знать о металлах https://metalprotection.com.ua от их свойств до применения в различных отраслях. Обзоры, советы, новости и информация о производителях для вашего удобства.

Всё для вашего ремонта https://reklama-region.com и строительства в одном месте! Практичные советы, современные решения и актуальная информация для успешного проекта.

Хотите построить дом https://samozahist.org.ua или сделать ремонт? На нашем портале вы найдёте лучшие решения и вдохновение для вашего проекта.

Официальный сайт https://luckyjetonewins.ru , где вы найдете актуальное зеркало и промоды на Лаки Джет.

программа организации производственного контроля Москва программа организации производственного контроля Москва

Строительный портал https://sinergibumn.com для тех, кто хочет знать больше о строительстве. Актуальные идеи, проверенные технологии и вдохновение для любого проекта.

Хотите стильный интерьер https://sitetime.kiev.ua Наш портал предлагает уникальные идеи, профессиональные рекомендации и примеры лучших дизайн-проектов.

Экспертный строительный портал https://smallbusiness.dp.ua для вашего проекта! Советы, новинки и инструкции для тех, кто хочет сделать всё идеально.

Строительный портал https://sushico.com.ua для профессионалов и новичков: от выбора материалов до готовых проектов. Легко найти подрядчиков, изучить современные технологии и воплотить идеи в жизнь!

Найдите всё о строительстве https://srk.kiev.ua и ремонте на нашем портале. Полезные статьи, актуальные технологии и лучшие практики ждут вас.

Планируете стройку https://texha.com.ua или ремонт? У нас вы найдёте проверенных специалистов, инструкции, материалы и проекты на любой вкус. Всё для комфортного строительства!

Всё о строительстве https://valkbolos.com и ремонте на одном портале! Гид по материалам, обзор инструментов, советы по дизайну и подбор подрядчиков. Создавайте дом своей мечты!

Преобразите ваш дом https://vineyardartdecor.com вместе с нами! На портале вы найдёте свежие идеи, советы по планировке и материалы для создания идеального интерьера.

Наш сайт – лучший выбор для тех, кто ищет китайские дорамы с русской озвучкой. У нас только профессиональный перевод, высокое качество видео и никакой навязчивой рекламы!

Ваш гид в мире строительства https://vitamax.dp.ua и ремонта! Обзоры, практические советы, дизайн-идеи и подбор профессионалов для реализации любых проектов.

Планируете ремонт или строительство https://vodocar.com.ua У нас всё, что нужно: от инструкций и советов до подрядчиков и обзоров материалов. Стройте с нами!

Полный справочник по строительству https://stroy-portal.kyiv.ua и ремонту: советы, инструкции, дизайн-решения и помощь с выбором материалов и подрядчиков.

Ремонт и строительство https://sota-servis.com.ua легко! Здесь вы найдёте инструкции, рекомендации, материалы и специалистов для успешного выполнения ваших задач.

Лучшие советы по строительству https://stroysam.kyiv.ua и ремонту на одном сайте! Найдите вдохновение, изучите обзоры и воплотите свои идеи с профессиональной помощью.

Users can activate No Deposit Free Spins for registration, with a special promo code, or through active bets. These are free spins. No Deposit Free Spins can be used on specific slot machines. We will tell you more about where to get No Deposit Free Spins for registration at a online casino in Canada. https://ca-feespins.com/

Сделайте ремонт https://tfsm.com.ua мечты с нашим сайтом! Советы, инструкции, рейтинг специалистов и новинки строительного рынка для вашего удобства.

Полный гид по строительству https://tsentralnyi.volyn.ua и ремонту: от планирования до отделки. Читайте, выбирайте и стройте с уверенностью и комфортом.

Стройте и ремонтируйте https://suli-company.org.ua с лёгкостью! Полезные статьи, инструкции, советы по выбору материалов и подрядчиков ждут вас здесь.

Портал о ремонте и строительстве https://buildingtips.kyiv.ua с полезными статьями, рекомендациями по выбору материалов и подрядчиков.

Простые решения для ремонта https://teplo.zt.ua и строительства! Идеи дизайна, рекомендации экспертов и проверенные материалы для вашего проекта.

TaskMy.ru – профессиональная помощь в решении задач любого уровня

TaskMy.ru – это надежный сервис, который предлагает качественную помощь в выполнении задач любых направлений: от технических расчётов и программирования до написания текстов и аналитики. Мы работаем быстро, эффективно и ориентированы на ваши требования.

Доверяя TaskMy.ru, вы получаете индивидуальный подход, точное соблюдение сроков и доступные цены. Оставьте свою задачу профессионалам – результат превзойдет ожидания!

Полный гид по строительству https://tsentralnyi.volyn.ua и ремонту: от планирования до отделки. Читайте, выбирайте и стройте с уверенностью и комфортом.

гг дроп промо как вывести скины с сайта ggdrop

Приветствую на https://bs2best.markets! Мы предлагаем надежные и проверенные покупки в интернете. Ознакомьтесь с нашими статьями о безопасности и легальности. Ваши покупки — наш приоритет!

Tormac.org https://tormac.org – это специализированный торрент-трекер, предназначенный для пользователей Mac-компьютеров. Сайт предоставляет широкий выбор контента, ориентированного на операционные системы macOS и iOS.

Сделайте ремонт https://tfsm.com.ua мечты с нашим сайтом! Советы, инструкции, рейтинг специалистов и новинки строительного рынка для вашего удобства.

A detailed history inter-milan-az.com of the Italian football club Inter Milan. From their first Scudetto to their Champions League victory.

mostbet казино фрибет mostbet

как пополнить 1win кыргызстан 1win partners вход

Klasyczna gra każdego kasyna, która w pełni oddaje atmosferę ryzyka, to bez wątpienia ruletka online w kasynie. Nowoczesne kasyna internetowe oferują dwa formaty tej gry: stołowy i z żywym krupierem. Zasady są identyczne dla każdego typu. https://ruletkagra.pl/

MLB Draft Betting https://bettingblog.website Your guide to the world of MLB draft betting. Expert predictions, top odds and detailed analysis will help you increase your chances of success. Bet and win with us!

Credit Union Mobile Home Loans https://blogcredit.tech are the perfect solution for buying or refinancing a mobile home. Affordable rates, easy application, and reliable support every step of the way. Take the first step toward your home with us!

Best Forex Trading Course https://blogforex.tech is your key to successful trading. Learn the secrets of professionals, study strategies and learn how to minimize risks. Master Forex easily and effectively!

Tennis betting https://yourmoneyblog.site best odds, predictions and analytics. Explore detailed match reviews, statistics and strategies to make successful bets. Use our tips and win!

Federal Gov Open Enrollment https://body-balance.online is your chance to upgrade or choose an insurance plan. Easy navigation, expert support, and a wide range of programs will help you make the right choice. Apply now!

Crypto Funk https://besttodaynew.com is a fresh look at cryptocurrencies. News, trends, guides and analytics for beginners and professionals. Find out how to get the most out of blockchain technology!

желтый топаз цена https://goldentopazway.ru/

No Credit Check Loans in Abilene TX https://daynewday1.com is fast access to money without unnecessary checks. Convenient terms, simple application and instant approval. Get financial help when you need it!

Home Equity Loans https://funnydays1.com How They Work, What Are the Terms and Benefits? Get the full details on how to use your home’s value for financial purposes. Find out more today!

Credit score requirements for FHA loans https://lifeofnews1.com minimum threshold and tips for improving. Find out how to increase your chances of getting a loan, as well as what affects approval. Detailed information for those who want to get a mortgage through FHA.

Auto loans from Community Credit Union https://sunnydays100.com are simple, affordable, and great value. Low interest rates and flexible repayment options make it easy to buy a new or used car.

программа производственного контроля учреждения программа план производственного контроля

Kevin Durant biography https://kevin-durant-az.org personal life, relationships, height, weight, shoe size and 2024 NBA statistics with the Brooklyn Nets.

Steve Rogers https://kapitan-amerika-az.com bravely fought the Nazis until a tragic accident left him frozen in the Arctic ice for years.

Kyrie Irving’s kyrie irving az com biography covers his personal life, height, flat-footedness, injuries, Muslim faith, vaccination stance, Boston Celtics stats, plus Nike shoes. Latest news for 2024.

Rafael Nadal rafael nadal date and place of birth, height, career highlights, childhood, tennis results, ATP rankings, records, injuries, Australian Open defeat, return to tournaments, career summary and latest news in 2024.

dma карта заказать

Daniil Medvedev biography daniil-medvedev-az.com personal life, wife and child. His tennis tournaments, matches against Nadal and Djokovic and becoming world number 1. Loss of top spot, Australian Open and latest news in 2024.

Biography of Roy Jones Jr. roy-jones-az.org How he became the first boxer to win the middleweight, super middleweight, super heavyweight and super heavyweight titles. Known for his explosive style, like Mike Tyson.

Коробки оптом https://giftbox-3.ru с логотипом на заказ маленький тираж и упаковочная бумага в коробку в Ижевске.

Dive into the exciting gaming world of 365 taya! Endless selection of games, fast withdrawals and fair play – everything for your pleasure.

Скачать музыку бесплатно https://muztab.net просто! Большой выбор песен, хиты всех времён и редкие записи. Удобный поиск, быстрая загрузка и безлимитный доступ. Ваш плейлист ждёт пополнения!

buy THC vape in Prague Cali weed for sale in Prague

Познакомьтесь с успешными игроками roulette players kz org в рулетку, которым удалось завоевать состояние в миллион долларов. Многие предлагают свои собственные советы, стратегии, секреты и многое другое. поделился.

Get to know Marco Asensio’s http://marco-asensio-az.org biography: personal life, Dua Lipa, romance rumors with girlfriend Sandra Garal, statistics, salary at Real Madrid and latest news.

Biography of Spanish footballer Dani Carvajal daniel-carvajal-az.org/ his personal life and marriage to his twin sisters along with Joselu. His career with Real Madrid and Spain in the Euros, knee injury and latest updates.

Didier Drogba’s didier-drogba-az.org biography covers his personal life, updates from 2018, Instagram, wife, career at Chelsea and goals.

Biography of Turkish footballer Arda Guler arda-guler-az.org/ midfielder for Real Madrid and the Turkish national team. Highlights include his careers at Genclerbirligi, Fenerbahce and Real Madrid, statistics, achievements, participation in Euro 2024 and news from his personal life and club in 2024.

Richarlison de Andrade’s richarlison biography covers his time at Everton, his move to Tottenham, his difficult childhood, his white hair like Ronaldo, the Brazilian national team and the latest news.

Biography of Argentine footballer https://mauro-icardi-az.org Mauro Icardi personal life, separation and scandal with Maxi Lopez’s ex-wife Wanda Nara, statistics, salary at Galatasaray, conflict with Lionel Messi, injuries and news.

Legendary Soviet goalkeeper Lev Yashin zinedine-zidane-az.com/ left a significant mark on football. He played for Dynamo Moscow and the USSR national team, and his career was filled with triumphs and memorable moments.

Roger Federer biography https://roger-federer-az.com retirement from professional tennis, Roland Garros, children. Career rivalry with Rafael Nadal. Latest tennis news.

Paolo Maldini’s biography paolo maldini photo, defender 2019, personal life, Instagram, Milan, salary, religion and news.

Biography of Brazilian footballer Ronaldinho https://ronaldinho-az.org personal life, son’s contract, current position. Club career, free kick goals, dribbling, jersey number, Ballon d’Or award, prison sentence. Latest news of 2024.

Biography of footballer casemiro az org Casemiro: personal life, wife and children. Career, statistics, salary at Real Madrid, Brazil national team, transfer fee, position, transfer to Manchester United and the latest news for 2024.

manga reader One Piece free online No Registration Manga Reader Free

Мы объясним на тему https://fisuticket.com/ с развернутыми ответами. Как быстро скачать официальное приложение 1xBet на любой смартфон. Процедура загрузки занимает всего несколько минут и доступна для всех устройств на базе Android и iOS. По завершении установки вы получите доступ ко всем сервисам компании и сможете делать ставки в любое время.

Biography for David de Gea david-de-gea-az com on a fan site. Known for his quick reactions and precise timing, he has managed to surprise fans all over the world. Manchester United to Fiorentina transfer, Atletico Madrid, personal life, children, height, weight and news.

Harry Maguire harry-maguire is an English footballer who is the captain and centre-back of Manchester United. He represented England at the 2022 World Cup in Qatar.

James Rodriguez james rodriguez biography: personal life, latest news, Instagram, goals, transfer to Rayo Vallecano, statistics and captain of the Colombian national team.

taya365 login taya365 app

Nicholas Jackson nicolas-jackson-az com is a Senegalese professional footballer who has taken the football world by storm with his play and achievements.

Biography of Jamie Bynoe-Gittens jamie gittens az org a winger for German club Borussia Dortmund, and an English footballer.

Biography Pau Victor pau-victor-az.org/ is a Spanish footballer who started in the lower divisions. Thanks to hard work, he got into a good youth team at FC Barcelona. He played for Girona and has good statistics.

taya 365 taya 365 casino login

When Huseyin and Naime hakan-calhanoglu welcomed their son Hakan to Monchengladbach, Germany, during the 1994 World Cup, they had no idea he was destined to become a star. Learn his biography, facts and news.

Biography of Dominik Szoboszlai dominik-szoboszlai-az.org a Hungarian footballer, midfielder for Liverpool and captain of the Hungarian national team.

Biography of Ollie Watkins ollie watkins an English striker for Aston Villa and the England national team. Find out about his career, clubs such as Exeter City and Brentford, height, age, achievements, participation in Euro 2024, personal life and latest news.

Francisco Conceicao http://francisco-conceicao-az.org was born into a family where football was already a part of the family, with a legacy built on hard work and passion. Juventus, Porto and Portugal national team appearances, brother Rodrigo, FIFA stats and news.

Biography of Emre Can emre-can a German footballer, midfielder for Borussia Dortmund and the national team. A career full of achievements and participation in Euro 2024, including games for Bayern, Liverpool and Juventus.

Biography of Spanish footballer Mikel Merino https://mikel-merino-az.org midfielder for Real Sociedad and the Spanish national team. Games for Borussia and Newcastle, height and age, achievements and participation in the 2024 European Championship.

Wout Weghorst’s wout-weghorst-az org background is similar to Jamie Vardy’s, as both players rose from relative obscurity to achieve success in football. Career, playing for Burnley and Manchester United, clash with Messi, participation in Euro 2020, World Cup 2022.

Growing up in the natural nuno mendes mountains of Sintra, Portugal, young Nuno Mendes quickly became a local sensation thanks to his impressive football game. He is playing for Paris Saint-Germain and Portugal at EURO 2024.

In the process of rising to popularity https://eberechi-eze-az.org Eze is now celebrated around the world for his footballing prowess, with many fans unaware of his difficult beginnings.

We present the story conor-gallagher-az.com of an athlete whose courage and will to succeed helped him overcome a terrible heart arrhythmia. Football clubs Chelsea, Crystal Palace, the England national team and Atletico Madrid.

Biography and statistics https://leandro-trossard-az.org from the life of football player Leandro Trossard. Sports career in football, playing for Genk and Lommel United, height and weight, participation in Euro 2024 and achievements.

A biography of Belgian footballer https://jeremy-doku-az.org Jeremy Doucoux, a winger for Manchester City and the Belgium national team. It covers his playing career, including his time with Anderlecht and Rennes, as well as his height and weight, his participation in Euro 2024 and achievements.

Full biography of Vitinha https://vitinha-az.org a player for Paris Saint-Germain and the Portuguese national team. Sports career, appearances for Porto and Wolverhampton, relationship with Messi, height and weight, achievements, participation in Euro 2024.

A versatile footballer fermin-lopez-az org who has developed rapidly in just six months. His club career at FC Real Betis and the national team, his height and weight, his achievements, his participation in the European Championship and the Olympics in Paris.

Biography of Austrian footballer https://marko-arnautovic-az.org Arnautovic Marko – games at FC Werder Bremen and Internationale, market value, achievements. Personal life, conflicts, rumors and latest news.

Biography of Federico Chiesa federico chiesa az org Italian winger for Juventus and the Italian national team. Career, Fiorentina, Euro 2024, transfer to Liverpool, family, wife Lucia Bramanti.

Biography of Austrian jorginho-az org footballer Arnautovic Marko – games at FC Werder Bremen and Internationale, market value, achievements. Personal life, conflicts, rumors and latest news.

Aurelien Tchouameni’s aurelien-tchouameni-az.org biography: personal life, date of birth, parents’ jobs, statistics at Real Madrid and Monaco, position, jersey number, 2024 updates.

Biography of Dayot Upamecano dayot upamecano az org Bayern star, France national team hero, early career start, Euro play-off participation, personal life and football news for 2025.

Biography of Portuguese bernardo-silva-az.com footballer Bernardo Silva: personal life, relationship with his wife, similarities with Bruno Fernandes. Current team, number on the field, reviews of fans who have sold out.

Biography of Spanish pedri-az.com/ footballer Pedri, statistics at Barcelona, ??games with teammate Gavi, joining the national team for the Euros.

Biography of Brazilian football player Rodrigo https://rodrygo-az.com photos of the striker of the Real Madrid club and the Brazilian national team, sports career.

Biography of football player antoine griezmann Antoine Griezmann: personal life, birth of children, national origin. Now his career, playing for Atletico Madrid.

Biography of Brazilian https://alisson-becker-az.com footballer Alisson: photo of the goalkeeper of the Liverpool club and the national team, sports career, playing for FC Inter and Roma, growth, achievements.

Riyad Mahrez http://riyad-mahrez-az.com all trophies and personal awards. Riyad Mahrez – biography of the striker on the field of the Al-Ahly Jeddah football club and the Algerian national team.

Biography of Brazilian footballer gabriel-jesus-az.com Gabriel Jesus: photo of the striker of Arsenal club and the Brazilian national team, sports career at Palmeiras and Manchester City clubs.

Manchester City manchester-city.com az officially known as Manchester City Football Club, is a professional football club based in Manchester, England. They compete in the Premier League, the top tier of the English football league system.

Нужен ремонт техники https://чинпочин.рус все услуги для вашего дома в одном месте! Выбирайте мастеров для ремонта, уборки или сантехнических работ. Качественный сервис, прозрачные цены и удобство использования.

Процесс получения диплома стоматолога: реально ли это сделать быстро?

“Ищете качественный кирпич напрямую от производителя? https://Muravey61.ru – ваш надежный поставщик строительных материалов в регионе! Мы предлагаем кирпич высшего качества по доступным ценам прямо с завода. Доставка точно в срок, широкий ассортимент, и гарантированное качество – всё, что нужно для вашего строительства. Закажите у нас и убедитесь сами, что с нами строить легко!”

Biography of Brazilian footballer Malcolm http://malcolm.com.az personal life, relationship with his wife. Salary at Zenit, career at Barcelona, ??Russian citizenship with Claudinho.

Tottenham Hotspur https://tottenham.com.az officially known as Tottenham Hotspur Football Club, is a professional football club based in Tottenham, in the London Borough of Haringey.

Biography of footballer iker-casillas-az.com Iker Casillas: personal life, separation from ex-wife Sara Carbonero.

Anti-Virus Tools Software FTP Active X Software

Biography of Spanish footballer Dani Carvajal dani carvajal personal life, marriage to Joselu and twin sisters. Performances at the Euro for Real Madrid and the Spanish national team.

Tobey Maguire’s https://tobey-maguire-az.com biography: personal life, memories of him, friendship with Leonardo DiCaprio, divorce from ex-wife. Role in Spider-Man films, career now.

купить диплом автошколы 2orik-diploms.ru .

Jackie Chan’s jackie chan biography: personal life in his youth, relationship with his wife, problems with his son and illegitimate daughter. Filming in the film “The Secret of the Dragon Seal”, dubbing of animated films.

Biography of actor Keanu Reeves keanu-reeves-az.com/ personal life, the tragic death of his child and his relationship with his common-law wife Jennifer Syme, artist Alexandra Grant.

usb software Security and Privacy Software

glory-casino-bd.online

Chelsea Football Club http://chelsea-fcl-az.com commonly known as Chelsea, is a professional football club based in Fulham, southwest London.

Biography of football player david-backham-az.com David Beckham: personal life now, relationship with his wife Victoria Beckham, rumors of infidelity with Rebecca Luz, raising children, style and hairstyle.

The UEFA Champions League champions-league-az com is an annual international football tournament organized by the Union of European Football Associations (UEFA) for the top-tier clubs in Europe.

Biography of fighter Jon Jones https://jon-jones-az.com personal life now, height, arm length. Fights with Cyril Gan and Daniel Cormier, UFC defeat rate, mixed martial arts statistics, champion titles.

Biography of racing driver Lando Norris lando-norris-az.com Childhood in the wealthy family of parents Adam Norris. Formula 1 career, podium finishes, McLaren driver contract, Max Verstappen trophy incident.

Welcome to the Kylian Mbappe kylian mbappe azerbaycan com fan site! Learn all about the talented footballer, his achievements, news and exciting moments on the pitch.

Biography of Zendaya Coleman zendaya-maree (Zendaya): modeling career, music and cinema, details of her personal life, ex-boyfriend Jacob Elordi, romance with Tom Holland.

Welcome to the Victor Vembanyama victor-wembanyama-azerbaijan.com fansite! Learn all about his career, achievements, and the greatness of this talented basketball player.

Welcome to the Mohamed Salah https://mohamed-salah-azerbaycan.com fans site! Learn everything about the great Liverpool and Egyptian national team player. Goals, achievements, statistics – it’s all here!