We strongly reject these unfounded allegations. We have data and research to prove that these allegations are not true, and would like to reiterate that the Sterlite Copper plant has been operating within all applicable environmental regulations and standards.

The plant is equipped with full-fledged air pollution control measures and adequate solid waste management facilities. The plant follows Zero Liquid Discharge since inception, and all the effluent is treated and recycled back into operations, so there is no effluent discharge. The regulator, TNPCB, carries out regular monthly sampling across all village bore wells and has found no abnormalities. (For details, please refer to slides in the pdf).

There is no scientific evidence for the allegations concerning health issues and the Crude Incidence Rate (Cancer incidence rate) at Tuticorin is much lower than the state average.

All the allegations have already been dealt with in Supreme Court 2013 judgment and the NGT 2013 judgment. The activists have unnecessarily raked up these issues again. We remain committed to a transparent dialogue with all the relevant authorities, regulatory bodies and our stakeholders.

We have spent over INR 500 Cr on environmental mitigation measures, particularly flue-gas desulphurization units with bag filters, modern technology based reverse osmosis plants and evaporators etc., and have implemented several other state-of-the-art environment protection measures. The rate of cancer in Tuticorin is far below the state average and any allegations linking the incidents of cancer or marine pollution with Sterlite Copper operations are unfounded. We are a zero liquid discharge company since inception and do not harm the marine ecosystem in any way.

The solid waste from effluent treatment plants is disposed in a Secured Land Fill designed in accordance with Central Pollution Control Board guidelines. The water samples from the piezometric bore-wells / dug wells are checked by the Tamil Nadu Pollution Control Board on a monthly basis inside the plant premises and in the nearby villages, and the samples do not reveal the presence of any marker pollutants namely arsenic and zinc, confirming that Sterlite’s operation are not polluting the groundwater.

Vedanta Resources has been committed to operating as a responsible business to the highest international standards of sustainability and corporate governance. At Tuticorin, all wastewater is treated and then reused in the operations of the plant, as is the case across all of Vedanta’s operations. We are focused on minimizing our environmental impact by achieving zero harm, zero waste, zero discharge and promoting social inclusion across our operations. Over the past two decades, Vedanta has worked tirelessly for the development of Tuticorin and its adjoining villages. The company remains committed to the town and state of Tamil Nadu.

FACT: The data suggests that the rate of cancer in the Thoothukudi is below the state average and hence does not rank first. Further, it is baseless to link that Sterlite’s operations can cause Cancer.

As per the Crude Incidence Rate (CIR) on cancer published by Department of Health, Government of Tamilnadu in the year 2014, Thoothukudi ranks 14 among male and ranks 25 among female out of 32 districts in Tamilnadu. Chennai, Kanchipuram, Coimbatore, Kanyakumari, Tiruvallur, Cuddalur are the top six districts predominant with cancer cases. This is also proved in the recent Policy Disclosure Note – 2017, released by the Health Department, Government of Tamil Nadu.

cms.tn.gov.in/sites/default/files/documents/hfw_e_pn_2017_18_0.pdf

The International Agency for Research on Cancer (IARC) has not classified sulphur dioxide as a human carcinogenic.

FACT: Sterlite Copper has been a Zero Liquid Discharge plant since the inception of the plant in 1995. All wastewater is treated in Effluent Treatment Plant followed by Reverse Osmosis Plant. The entire treated water is then recycled back into operations, and there is no discharge of any water to the sea. Hence our operations does not impact marine life.

This Zero Discharge nature of our operations has been endorsed by the NEERI Committee in 2011. The committee, along with the petitioners – Mr. Vaiko (along with Nityanand Jayaraman), CPI, and National Trust for Clean Environment visited the plant to confirm the Zero Liquid Discharge nature of our operations. Further, a bio-diversity study conducted in the 10 km radius of Sterlite Copper, Thoothukudi by Forest Research Institute, Dehradun has also confirmed that our operations do not have an impact on the local marine life. This allegation has been adequately handled and deliberated in depth by Honorable Supreme Court, and a clear verdict was pronounced way back in 2013, putting all these allegations to rest.

FACT: The joint inspection carried out by TNPCB and CPCB in 2012 confirms that the industry has complied with the prescribed Green belt requirement. We have also planted an additional greenbelt in our township, which is located in close proximity to the plant.

FACT: Sterlite Copper is located in SIPCOT industrial complex wherein other red category chemical industries are located. Sterlite Copper is Zero Liquid Discharge Company and does not affect the marine ecosystem in any manner. Further, the current EIA rules, 2006 stipulate a distance of 10km from eco-sensitive areas, which is reduced from 25 km stated previously.

Additionally, Gulf of Mannar is not yet notified as National Marine Park as per Environmental Protection Act or as per Wildlife Protection Act. It was only intended to be declared as National Marine Park, but till date, it is not notified. This matter was debated in detail in the Hon’ble Supreme Court (Case: Sterlite Industries (India) Ltd, Etc., Versus Union of India & Ors. Etc.), and both State Government and Central Government accepted that it is not yet notified as National Marine Park.

FACT: 3070 (70%) of our employees are from Tamilnadu of which 2150 are from Thoothukudi.

FACT: As stated earlier Sterlite Copper is zero liquid discharge company from the date of inception. The solid wastes from effluent treatment plants are disposed in a Secured Land Fill designed as per CPCB guidelines. Other solid wastes, such as copper slag and gypsum which are high volume and low effect wastes, are being utilized for sustainable applications such as cement, road building and shot blasting applications. The slag is particularly tested for its non-leachable, non-toxic characteristics from reputed Government institutes of the country and accordingly put to use for sustainable applications such as landfilling, road construction, use in the cement industry, and sand-blasting. 100% of the generated copper slag is being utilized for the above-stated applications.

As stated earlier Sterlite Copper is zero liquid discharge company from the date of inception. The solid wastes from effluent treatment plants are disposed in a Secured Land Fill designed as per CPCB guidelines. Other solid wastes, such as copper slag and gypsum which are high volume and low effect wastes, are being utilized for sustainable applications such as cement, road building and shot blasting applications. The slag is particularly tested for its non-leachable, non-toxic characteristics from reputed Government institutes of the country and accordingly put to use for sustainable applications such as landfilling, road construction, use in the cement industry, and sand-blasting. 100% of the generated copper slag is being utilized for the above-stated applications.

The water samples from the piezometric bore-wells / dug wells are being checked by Tamilnadu Pollution Control Board on monthly basis inside the plant premises and in the nearby villages.

If Sterlite Copper were polluting the groundwater, we would expect to see evidence of marker pollutants like copper, zinc and arsenic. The samples do not reveal the presence of these marker pollutants. It can thus be concluded that Sterlite’s operation is not polluting the groundwater.

This has also been confirmed in NEERI’s report, “Inspection of M/s Sterlite Industries (India) Ltd – Assessment of Environmental Pollution Status” in 2011, which was submitted to the Honorable Supreme Court of India.

Pollution database of Tamil Nadu http://tnenvis.nic.in/Water%20Pollution%2023-04-2014%20final.pdf ranks Thoothukudi (8% contamination) at 23rd place in the state as against the Dharmapuri district (88% contamination) with regard to groundwater contamination in Tamil Nadu.

This allegation has been further adequately handled and deliberated in depth by Honorable Supreme Court, and a clear verdict stating that Sterlite Copper is not contaminating the groundwater has been pronounced in 2013.

FACT: Based on the rainfall data received from the National Meteorological Department, Chennai the annual average rainfall before Sterlite operations started was 569 mm (from 1990 to 1996). However, annual average rainfall after Sterlite operations commencement is 749 mm (1997 to 2015), which shows that there is a 32% increase in rainfall. Also, on 14th March 2018, Thoothukudi recorded highest ever rainfall in last 63 years.

Hon’ble Supreme Court has observed from the earlier NEERI reports (1998, 2005) that there were certain deviations in some parameters but also observes that it does not warrant a conclusion that the plant of the appellant will not be able to take remedial steps to improve the environment. Subsequently, the company undertook remedial measures as per TNPCB recommendation to eliminate the possibility of any such deviations, and since then all the parameters have been regularly monitored by authorities and found to be within prescribed norms.

In addition to the above, in some years between 1999 – 2005 and 2008 – 2013, the plant operated under a deemed consent. As per Water Act 1972, if the consent is not renewed by any Pollution Control Board after the application, it will be a deemed consent. In these years, the Consent to Operate was not renewed by TNPCB though we had applied and paid fees for renewal on time. During this non-renewal period all inspections, air and water sampling were conducted regularly by the TNPCB and found within prescribed limits. Though the consent was renewed later, Hon’ble Supreme court cited this non-renewal period as a concern and hence asked us to deposit INR 100 crores to the District Collectorate to carry out remedial action in case of any environmental damage.

FACT: During copper smelting operations, the copper concentrate is smelted at 1200 Deg C, and the iron content in the copper ore is separated out in the form of granulated iron silicate. At this very high temperature, all the organic and inorganic compounds get mineralized and produce a solid mass which is highly stable and non-leachable in normal conditions. This by-product is stored in our premises briefly and sold for various beneficial applications such as landfilling, road construction, use in the cement industry and sand-blasting. 100% of the generated copper slag is being utilized for the above-stated applications. After conducting stringent tests, the Central Pollution Control Board has declared Ferro Sand (or Copper Slag) as non-hazardous. It can be used for cement manufacturing, filling up of low lying area and road construction. MoEF also has declared Ferro Sand as non-hazardous through “Hazardous Wastes (Management, Handling and Transboundary Movement) Rules, 2008, Notification on 24.09.2008” and terms it as “high volume low effect waste.”

We also conducted various technical studies through premier research institutions of India such as M/s National Metallurgical Labs (NML), Chennai; M/s Indian Toxicology Research Centre (ITRC), Lucknow; M/s National Council for Cement & Building Materials (NCCBM), Haryana; and M/s Central Road Research Institute (CRRI), New Delhi. All the studies have concluded positive results for Ferro Sand, declaring it as a highly stable material, non-toxic in nature, possessing good properties as raw material for cement manufacturing and road construction. Based on these studies, BIS standard has approved use of this copper slag as a replacement to natural fine aggregates up to 50%.This is a clear example of sustainable use of industrial waste and protect environment by avoiding use of natural mineral such as river sand.

FACT: The safety performance of the company has improved over a period of time and has reached to a stage where the records and practices are at par with international smelters. The company follows not only the national standards but also the international standards such as International Finance Corporation (IFC) & International Council of Mining & Metals (ICMM). The Lost Time Injury Frequency Rate (LTIFR) is the normal index being monitored across global metal and mining companies which is nothing but the number of lost time injuries for every million man-hours worked. The LTIFR of Sterlite has reached 0.12 which is at par with international benchmark.

The company has been accredited with the “British Sword of Honour” in December 2017, which is a highly coveted award in the field of safety and this was awarded after a British team carried out extensive audits across the facility. However, when injuries occur within the plant premises, it causes us to re-examine our systems and take steps to improve on any gaps that may have led to the accidents. To those injured, we provided medical assistance, paid-time-off, and any other support that they may require to fully recover and get back to work. In case of the unfortunate event of a fatality, we provide full financial assistance to the families of the deceased, ensuring that they are able to continue to remain financially secure.

FACT: Water supplied for industrial purpose is drawn from the fag end of the downstream, which otherwise enters the sea and hence does not affect water for agriculture, domestic or drinking purpose. Sterlite Copper consumes only 19% of the water supplied to industries in Thoothukudi out of which most of it is sourced through desalinated facility. Water conservation is a key priority of Sterlite Copper and various initiatives like rainwater harvesting and Reverse Osmosis plant has yielded excellent results. For the expansion project, Sterlite Copper will only be using desalinated seawater and water from treated sewage.

| Allegation Calculation: Total H2SO4 capacity = 4200 tpd 110% capacity = 4620 tpd At 2 kg/T acid produced, design emission = 9240 kg/day Q (kg/hr) = 9240 kg/24 hours = 385 kg/hr Height (as per CPCB norms) = 14Q(E+0.3) = 14 x 385(E+0.3) = 14 x 5.97 = 83.5 metres |

Calculation as per current norms: Total H2SO4 capacity = 2100 tpd 110% capacity = 2310 tpd At 1 kg/T acid produced, design emission = 2310 kg/day Q (kg/hr) = 2310 kg/24 hours = 96.25 kg/hr Height (as per CPCB norms) = 14Q(E+0.3) = 14 x 96.25(E+0.3) = 14 x 3.94 = 55.1 metres |

FACT: Sterlite is alleged to have dumped Copper Slag in the Uppad Odai, which had diverted the water and caused flood in the Tuticorin town. Sterlite sold the copper slag to a third party for developing his low-lying land in Pudukottai for construction of a container yard. The material was sold in the year 2009 – 2010. Tuticorin had received higher month total and 24 hour maximum rainfall in the year 2012 and 2014 which did not result in any flood of this nature. The reason for the flood was due to delayed opening of the gates at the downstream and restricted containment area due to sediment and plantation.

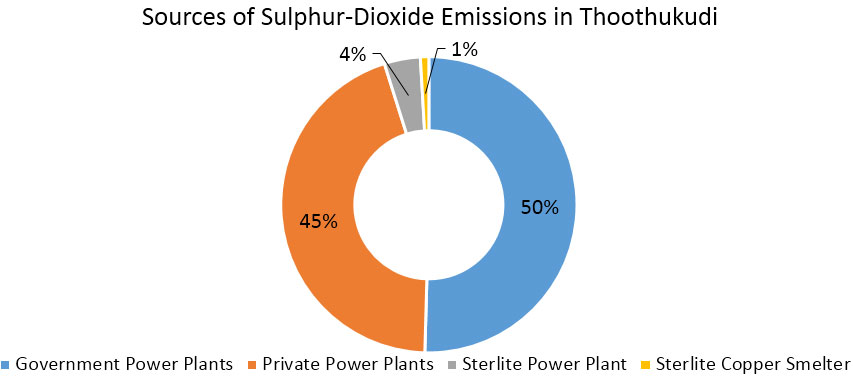

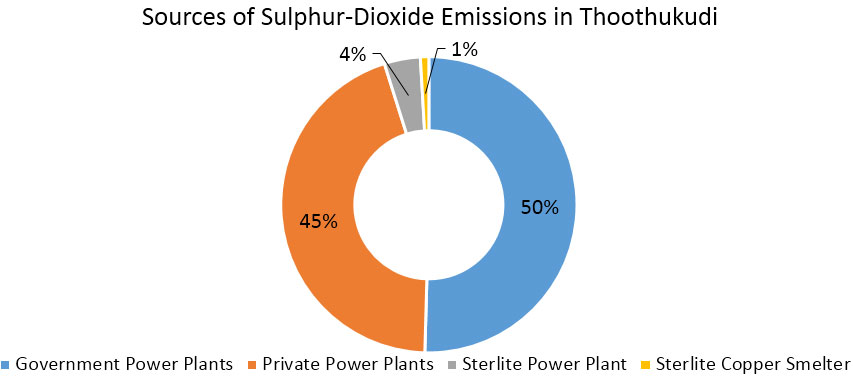

FACT: Thermal Power Plants are one of the major sources of Sulphur Di-Oxide, as there is no mechanism in-place for arresting or converting the Sulphur Di-Oxide. Coal contains 0.5% to 2.5% Sulphur, which when combusted generates Sulphur Di-Oxide. At Sterlite Copper, we have installed 2 nos. of Sulphuric acid plants to convert Sulphur Di-Oxide into Sulphuric Acid, the emission norms for SO2 are fixed by the Pollution Control Boards. The norms permit us to emit 1 KG of SO2 for every MT of acid produced, we operate at a much lower actual of around 0.7 KG per MT of Acid generation. The Copper smelter contributes to less than 1% of the total SO2 emissions in Tuticorin.

| Power plants | Capacity MW | Sulphur Di Oxide emitted MT / Day | Sulphur Di Oxide Share % sage |

|---|---|---|---|

| TTPS | 1050 | 118.44 | 25.84% |

| Costal Energy | 1200 | 135.36 | 29.53% |

| IndBharath- SAMINATHAM | 300 | 33.84 | 7.38% |

| IndBharath – E.V | 189 | 21.32 | 4.65% |

| NTPL | 1000 | 112.80 | 24.60% |

| DCW (Cogen + Coal) | 108 | 12.18 | 2.66% |

| IBETL (Bio mass) | 20 | 2.26 | 0.49% |

| Vedanta Thermal Power Plant | 160 | 18.05 | 3.94% |

| Sulphuric Acid Plant 1 | 2100 TPD | 2.10 | 0.46% |

| Sulphuric Acid Plant 2 | 2100 TPD | 2.10 | 0.46% |

| Total | 458.45 | 100.00% |

India’s current capacity is currently around one million tonnes. With a capacity of 400,000 tonnes, Vedanta currently holds a 33% market share in the country’s refined Copper demand of around 675,000 TPA tonnes. Imports contribute around 33%.

Sterlite Copper contributes approximately $295 million to the exchequer.

The economic impact on the Tamil Nadu government needs to be substantiated, however the overall socio-economic impact of the closure on the state is significant. Over the past 22 years, Vedanta has successfully developed Tuticorin and has played an important part in the region’s economic development. This has indirectly helped make Tuticorin, rank as the third district in the State on the Human Development Index. Sterlite Copper is the fifth largest company in Tamil Nadu in terms of turnover and accounts for 1.6% of the State’s GDP. It is the only private sector company contributing around 12% of Thoothukudi VOC Port’s revenue.

With revenue in excess of $3.3 billion, the smelter contributed $295 million to the exchequer in FY17.

More than 70% employees at the smelter are from Tamil Nadu and the plant operations impacts more than 20,000 people engaged in various supplier and customer units. The employees of Sterlite Copper contribute approximately $373,000 per month towards the economy of Thoothukudi district in-terms of their personal spend, which amounts to a tax contribution of around $37,300 per month to the government.

Among other key highlights, the plant engages about 1000 trucks/tankers on daily basis with consistent load, thereby providing livelihood to around 9,000 truck drivers and cleaners per month. We have over 650 supply and service partners and we help them generate a business of close to $134 million every year.

We supply 250,000 MT per annum of Copper to the domestic industry which customers now need to import at a cost of $2 Billion / annum resulting in a huge forex outgo and at a higher cost.

Moreover, for the people of Tuticorin and especially the communities around us, there is a bigger loss due to stoppage of Community development initiatives which touched more than 2.5 lac lives, as these were spread in areas such as Health, Education, Livelihood, Infrastructure, Income generation projects for Women etc.

Aside from copper, Sterlite is the only domestic supplier of phosphoric acid with a capacity of 220,000 MT, which is a key raw material for fertilizer manufacturing. It is the largest supplier of Sulphuric acid in Tamil Nadu, which is used in the detergent and chemical industries. Stoppage of the smelter could have an adverse impact on domestic fertilizer production as companies would have to look for import sources.

Prices of Sulphuric acid have risen three to four times because of the shortfall in supply due to the shutdown, and numerous small and medium size industries have had to shut due to lack of these raw materials. This will directly impact the livelihood of thousands of families across India.

On the community front, Sterlite Copper has always listened to the community needs and has impacted lives through projects focusing on Education, Health Care, Child Care, Women Empowerment, Infrastructure, Livelihood, Agriculture and Animal Husbandry.

The company identifies the requirements of the local community and has provided necessary support in developing the livelihood of the community. One of the major effort of the initiatives in being invested in identifying children and providing an access to quality education to the local community.

Health on Wheels: An initiative where a bus with medical facilities and medicines go around the surrounding villages and provide them with required medication. Also identifies pregnant woman and provides adequate antenatal care

Child Friendly Villages: Initiative covers babies from birth till the age of 3. Identifies the new-born babies in the surrounding villages, on the occasion of their first birthday, this initiative ensure the Birth Certificate of the child and facilitates in getting necessary medical support for the child.

Kushi: An initiative in which, the company has set up 10 Kushi centers across Tuticorin. To provide food – nutritional health, quarterly medical check-up and nursery education. The projects benefits 320 children of age 03 to 06 years and ensure them to be school-ready. As part of the initiative a growth chart is being maintained – to eradicate mal-nutrition.

Ilam Mottukal: The importance of girl education is of the utmost importance, as the drop-out of girl students are on the rise. As part of the initiative the company has launched in 94 government and aided primary schools covering 8050 girl children in the district to ensure every girl child is provided with quality school education in an enabling environment to realize her fullest potential for the consecutive five years. As part of the initiative, the company provides evening tuition centre, Educational Kits.

Teach Them Young: An adolescent initiative focused on sustained educational support to students from 11th grade to Graduation (Diploma / professional / BE / MBBS / Post-Graduation). The students enrolled are provided with financial assistance to pursue their education.

Tamara Muthukkal: Under this initiative, the company provides skill development courses to the community and enabled them to get employed in various fields from hospitality to manufacturing industries. A total of 6 skill development centre are located across Tuticorin with skill development courses ranging from welding, sewing machine, Software: Tally, Forklift operation and electrical. This initiative is carried out in association with IL&FS and is generally a 45 day training.

Sakhi: Enables formation of Self Help Groups (SHG) and provide income generation training; to enable additional income to the women from the nearby villages.

WaSH: Water, Sanitation and Health – as the name suggests, it enables to provide a drinking water, provide Public and school sanitation infrastructure and conducts frequent medical camps and eye camp to the nearby villages in a periodical manner.

Agricultural Support: Provide hybrid seeds to the farmers and de-silting of Tamirabarani for efficient flow of water in the river to agricultural lands

Infrastructure: Apart from school blocks, the Company has built the pediatric complex of the Tuticorin Government Hospital.

Apart from the local community, the company developed and maintains the iconic MGR Park in the town, which is vacation retreat to a number of migratory birds and has developed the Tiruchendur round about and various bus shelters and street lights across the town.

The company has assiduously driven the lifeline projects for over 20 years and reached 2.8 lakh people in Thoothukudi.